EDI is a new type of water treatment method that combines electrodialysis (the scene where the charged solute particles in the solution migrate through the membrane under the influence of an electric field) and ion exchange.

Electrodeionization (EDI) is a water treatment technology that utilizes electricity, ion exchange membranes, and resin to deionize water and separate dissolved ions (impurities) from water. It differs from other water purification technologies in that it is done without the use of chemical treatments and is usually a polishing treatment to reverse osmosis (RO). There are also EDI units that are often referred to as continuous electrodeionization (CEDI) since the electric current regenerates the resin mass continuously. CEDI technique can achieve very high purity, with a conductivity below 0.1 μS/cm.

Laboratory water purification system is one of the commonest equipment for scientific researchers, mainly used to produce ultrapure water for experiments. The great importance of ultrapure water is obvious in that water is an essential and numerously used reagent in the experiment process.

EDI is a replacement technology for the traditional ion exchange mixed bed process. The emergence of EDI is an advancement in water treatment technology, marking that the water treatment industry has entered the ranks of the green industry. It organically combines traditional electrodialysis technology and ion exchange technology to continuously produce high-quality pure water, but does not need to use acid or alkali, completely get rid of the problems of acid and alkali consumption, chemical waste liquid pollution, etc., so as to truly achieve Clean Production.

As a kind of deionized water equipment, the laboratory ultrapure water machine primarily adopts solutions such as reverse osmosis(RO), electrodialysis, ion exchange, and EDI. Among them, electrodeionization (EDI), is a new type of pure water and ultrapure water treatment technology gradually developed in the history of pure water production technology. The emergence of EDI is revolutionary progress, marking that the water treatment industry has finally entered the league of the green industry.

The advanced technology is rapidly gaining acceptance by virtue of good environmental protection and accessible operation, which has come into wide application in pharmaceuticals, electronics, electric power and chemical industry, etc.

Electrodeionization (EDI) is an electrically-driven water treatment technology that uses electricity, ion exchange membranes and resin to remove ionized species from water.

What does Electrodeionization remove from water?

EDI removes ions and other charged species from water, for example salts and organic acids.

What are the benefits of Electrodeionization?

The ion exchange beds in the EDI systems are regenerated continuously so that they do not exhaust in the same way as ion exchange beds that are operated in batch mode. As the impurities are removed via the concentrates, they do not build-up and exhaust the resin. An EDI unit may operate for many years before a replacement is required. Typically product water resistivity of >15 MΩ.cm is consistently achieved using this process. This technology can be used as an alternative to single-use purification cartridges. As well as the practical advantages and reduction in down-time of avoiding changing cartridges, EDI can also deliver more consistent purity than single-bed ion-exchange systems that may release weakly bound ions as the media exhausts. The smaller volumes of resin in an EDI module (compared to an ion-exchange bed) also reduce the release of organic impurities.

What is EDI?

Electrodeionization, abbreviated as EDI, scientifically integrates electrodialysis and ion exchange technology into one to remove ionized species from water. This process combines ion-exchange resins and ion-selective membranes, which are used to move ionic impurities into a waste or concentrate water stream, leaving purified product. As impurities leave via the concentrate water stream, their buildup does not exhaust the resin, and it prolongs the resin lifespan. Water resistivity of >15 MΩ-cm may be achieved by using this process.

How EDI works

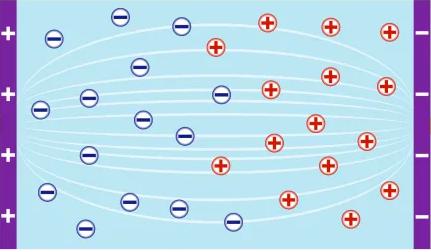

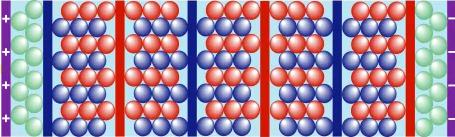

The EDI device fills and sandwiches the ion exchange resin between the anion and cation exchange membranes to form an EDI unit. The working principle of EDI is shown in the figure below. In the EDI module, a certain number of EDI units are separated by a mesh to form a concentrated water chamber. In addition, cathode and anode electrodes are arranged at both ends of the unit group. Driven by the direct current, the anions and cations in the water flow through the fresh water chamber respectively pass through the anion and cation exchange membrane into the concentrated water chamber and are removed in the fresh water chamber. The water passing through the concentrated water chamber takes the ions out of the system and becomes concentrated water. EDI equipment generally uses reverse osmosis (RO) pure water as EDI feed water. The conductivity of RO pure water is generally 2-40μS/cm (@25℃). The resistivity of EDI pure water can be as high as 18 MΩ.cm (25°C), but according to the use of deionized water and system configuration settings, EDI pure water is suitable for the preparation of pure water with a resistivity requirement of 10-15MΩ.cm (25°C)

How does Electrondeionizaton work?

EDI has the following advantages,compared with mixed ion exchange technology

The process flow of the laboratory ultrapure water machine is generally as follows: Pretreatment—High pressure pump—RO membrane—Ion exchange column (or EDI)—UV lamp—Ultrafiltration (or microfiltration)- –Terminal filter.

Compared with ion exchange technology, EDI as a new technology has the following advantages:

- Stable water quality

- It is easy to realize fully automatic control

- No shutdown due to regeneration

- No need for chemical regeneration

- Low operating cost

- No sewage discharge

The main factors restricting the promotion of EDI in the laboratory

- The user is worried that the early purchase cost of EDI ultrapure water machine is relatively high

- Worry about the service life of EDI

- The user is worried that the EDI replacement cost is too expensive

Why advocate EDI unit? Low maintenance!

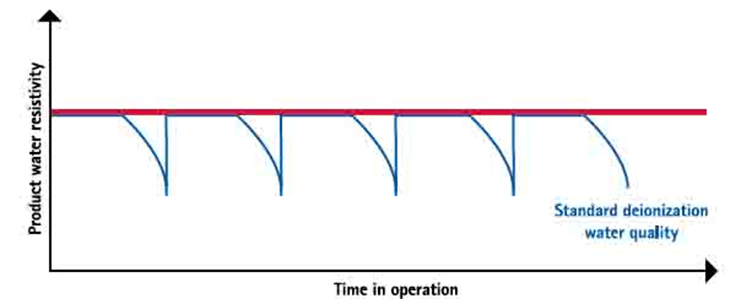

Normally, we first perform reverse osmosis and then remove the remaining impurities by ion exchange resin on raw water when using a laboratory water purification system. Therefore, for any industry laboratory, reverse osmosis membrane and ion exchange resin are both consumables. When the ion exchange resins are about to be depleted, they begin to release weakly ionized substances including some phosphates, silicates and nitrates. And if the colour of the resins has changed, we recommend immediate replacement because the resins, in this case, have lost their ion exchange function.

The above chart depicts the tendency of water resistivity value to change over time in the case of deionization. When the water resistivity drops to the lowest point, it means that the water quality has also become pretty awful. That is, we need to replace the resin directly. Besides, we can also see that the frequency of resin replacement is fairly high.

While in EDI water purification equipment, under the action of a direct-current electric field, water is ionized into H+ and OH- ions to continuously regenerate the resin filled in the bottom layer, so the water quality is properly guaranteed to be constant. As a result, the longer the resin replacement cycle, the lower its frequency. It is the non-complicated water purification process that greatly simplified the labour intensity, easy training within the trainee to accept.

Advantages of EDI unit:

No regeneration chemicals

There is no need to collect, store and dispose of hazardous chemical wastewater. As a result, the new EDI process greatly simplifies the system compared to conventional processes.

Stable water quality

Ion exchange and regeneration are synchronized with the EDI water system so that the water quality is very stable. Unlike mixed beds, the effluent quality is affected by ion leakage at the beginning and end of each regeneration cycle.

Recyclable

The production of electric desalination is continuous, eliminating the need for complex regeneration operations during the mixing process and reducing many spare types of equipment. There is no need to set up operators and operating procedures related to the recycling work.

Low operating cost and maintenance

EDI equipment requires only electricity to operate, while mixed bed technology requires extra acid and alkali. Therefore, ultra-pure water equipment reduces operating costs by saving acid and alkali. No exchange of spent resins or cartridges saves cost.