Are you in the market for a biological safety cabinet? This crucial piece of laboratory equipment is vitally important to ensure the safety of laboratory workers and the integrity of experiments. In this post, we’ll look at 9 key factors to consider when selecting a biological safety cabinet to ensure you select the right model for your needs. From airflow and HEPA filters to energy efficiency and ergonomics, we’ll cover it all so you can make an informed decision.

1. Biosafety Level

When selecting a biological safety cabinet, it is crucial to consider the biosafety level of the materials being handled. Biosafety levels (BSLs) are a set of guidelines established by the Centers for Disease Control and Prevention (CDC) that indicate the degree of risk associated with handling infectious materials. The appropriate BSL for a laboratory depends on the type and severity of the pathogens being handled. A biosafety cabinet that is not designed for the appropriate BSL can put laboratory workers at risk of exposure to hazardous materials. To ensure safety and compliance, it is important to select a biological safety cabinet that is specifically designed for the biosafety level of the materials being handled.

| Biosafety level | Description | Application Scene | Examples of Pathogens | Cabinet Requirements |

| Biosafety level 1 | Low risk | undergraduate and secondary education labs with non-pathogenic microorganisms | Bacillus subtilis, Naegleria gruberi, and infectious canine hepatitis virus | Simple safety measures such as handwashing sinks are usually sufficient |

| Biosafety level 2 | Moderate risk | Clinical, diagnostic, teaching with indigenous moderate-risk agents that connected to human disease | Hepatitis B virus, HIV, Salmonella, and Toxoplasma | Tasks entailing aerosol must be performed in BSC or safety centrifuge vessels. In addition, personal protective gear should be utilized in conjunction with handwashing basins and decontamination systems for waste. |

| Biosafety level 3 | High risk | clinical, diagnostic, teaching, research, or production settings, that have the potential to cause lethal respiratory infections | Mycobacterium tuberculosis, SARS-CoV-2, St. Louis Encephalitis virus, and Coxiella burnetiid | Class II cabinet, appropriate ventilation systems need to be up to standard to reduce the release of hazardous aerosols. |

| Biosafety level 4 | Extreme risk | Handling agents or pathogens that are potentially life-threatening and have no current vaccine or treatment | Ebola, Lassa fever virus, Marburg or Congo-Crimean hemorrhagic fever. | In glove box laboratory, Class III cabinet with additional protective measures, or with a full-body air-supplied positive-pressure suit. |

2. Stable and Accurate Airflow

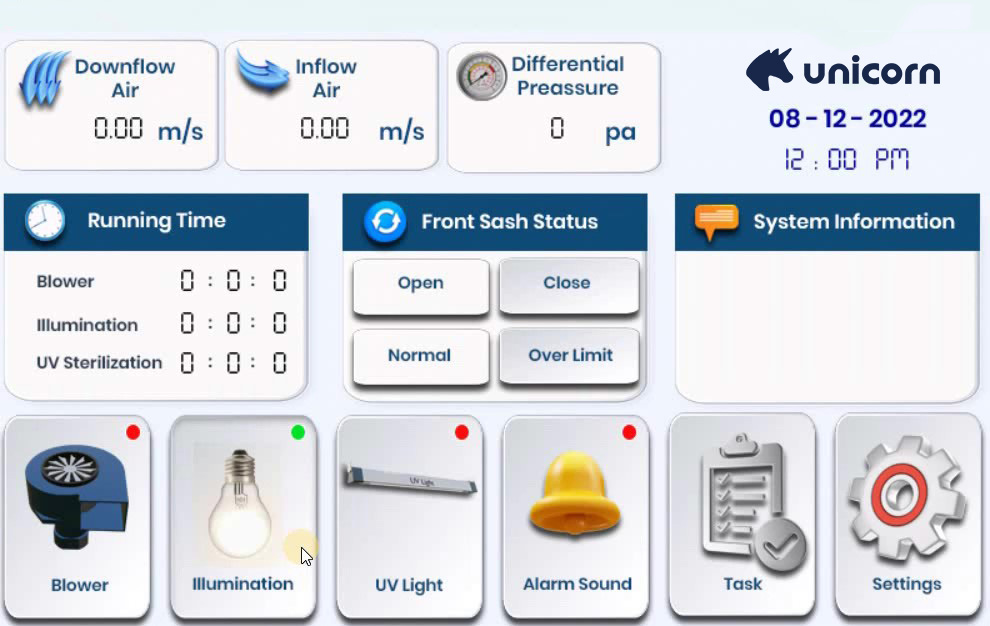

The velocity of air entering and exiting the cabinet must be carefully monitored and kept within the manufacturer’s specified range for optimal performance when selecting a biological safety cabinet.

It is crucial to ensure that the velocity of inflow and downflow of the biological safety cabinet (BSC) is within the manufacturer’s specified range because it directly affects the level of protection offered by the cabinet. The inflow velocity refers to the speed at which air is drawn into the cabinet, while the downflow velocity refers to the speed at which air is directed down over the work surface and out through the HEPA filter.

If the inflow velocity is too low, contaminants from the laboratory may be drawn into the cabinet, compromising the safety of the experiment and increasing the risk of contamination. On the other hand, if the inflow velocity is too high, it can disrupt the smooth flow of air in the cabinet, leading to turbulence that can cause the release of contaminants into the laboratory environment.

Similarly, if the downflow velocity is too low, contaminants from the experiment may not be effectively contained within the cabinet, leading to a potential safety hazard. Conversely, if the downflow velocity is too high, it can create turbulence that disrupts the smooth flow of air in the cabinet, leading to the release of contaminants into the laboratory environment.

Therefore, it is important to measure and maintain the velocity of inflow and downflow within the manufacturer’s specified range to ensure the highest level of protection for both the operator and the experimental materials. A simple and intuitive spreadsheet table can be created to help readers understand the importance of maintaining velocity within the specified range and how to measure it properly. The table can include columns for the recommended inflow and downflow velocities, the acceptable range of velocities, and the method of measuring velocity.

3. Filter and Body Integrity

The filter integrity test is a critical component of ensuring the safety of a biological safety cabinet (BSC). The BSC is designed to provide a safe and sterile working environment by filtering the air that enters and exits the cabinet. The filters within the BSC are responsible for trapping harmful particles and microorganisms, and preventing them from contaminating the laboratory environment. Over time, filters can become clogged or damaged, which can compromise their effectiveness and lead to contamination.

A filter integrity test is conducted to confirm that the filters are functioning as intended and are not compromised in any way. The test involves subjecting the filters to a challenge, such as a aerosolized solution of a known particle size, and then measuring the efficiency of the filter in capturing those particles. This ensures that the filters are capable of trapping harmful particles and microorganisms, and preventing them from escaping the cabinet and potentially contaminating the laboratory environment.

By regularly performing filter integrity tests, laboratory personnel can ensure that their BSC is functioning properly and providing the level of protection needed for their work. It also helps identify any issues with the filters before they become a problem, allowing for timely replacement and maintenance. Ultimately, this helps to minimize the risk of contamination and ensure a safe working environment for laboratory personnel and the materials they are working with.

By conducting body containment tests during the manufacturing process, the manufacturer can ensure that the BSC is functioning as intended and meets the required biosafety level. This provides an additional layer of safety for laboratory personnel and helps to minimize the risk of exposure to harmful materials. It is important for laboratories to only purchase BSCs that have passed the body containment test during manufacturing to ensure the safety and effectiveness of their work.

4. HEPA or ULPA Filters

The filter is a key piece of a Biological Safety Cabinet (BSC). Presently, two varieties of filters are employed by the containment device: HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Particulate Air) filters. The main difference between the two is their efficiency in removing particles from the air. HEPA filters are capable of removing 99.97% of particles that are 0.3 micrometers or larger, while ULPA filters can remove 99.999% of particles that are 0.12 micrometers or larger.

HEPA filters are more commonly used in biosafety cabinets and are suitable for most laboratory applications. They are also more cost-effective compared to ULPA filters. However, HEPA filters may not be sufficient for certain applications that require higher levels of air filtration, such as working with hazardous biological agents.

ULPA filters offer a higher level of air filtration and are recommended for applications that involve highly infectious agents or toxic chemicals. They are more expensive than HEPA filters and require more energy to operate, which may result in higher operating costs. ULPA filters may also require more frequent replacement than HEPA filters.

Overall, the choice between HEPA and ULPA filters depends on the specific application and level of biosafety required. It is important to consult with biosafety experts and manufacturers to determine the appropriate type of filter for a given laboratory operation selecting a biological safety cabinet.

5. Easy of Use

User-friendly Design

The cabinet should have an intuitive design that allows users to access its contents with ease. Its ergonomic layout should be comfortable and inviting, allowing users to access their equipment without any fuss. A user-friendly design also encourages users to stay organized, with clear labels and dedicated storage spaces for each item. Furthermore, the cabinet should be easy to open and close. With a user-friendly design, you can ensure easy access to the equipment inside your cabinet and ensure that it remains neatly organized.

Ergonomics

Designing a cabinet with ergonomics in mind is essential for comfortable and efficient operation. Allowing for an ergonomic design can reduce user fatigue, making tasks easier and more enjoyable. The cabinet should be designed to fit the user’s body size, posture, and physical abilities to ensure a comfortable and safe work environment. Additionally, the cabinet should be equipped with adjustable heights and angles, as well as adjustable levers, to provide a personalized experience for the user. With an ergonomic design, the user can be sure that they are working safely and efficiently, allowing them to complete their tasks with ease.

Accessibility

Ensuring that all parts of the cabinet are easily accessible is essential for efficient maintenance and repairs. With a few simple adjustments, the cabinet can be transformed into a workshop of sorts, allowing for quick and easy access to any part of the cabinet. Whether it’s a minor tweak or a complete overhaul, having access to all areas of the cabinet will make the process simpler and more efficient. Plus, the added convenience of being able to repair and maintain the cabinet with ease will be a huge benefit to any user.

6. Single-piece or Multi-piece Work Tray

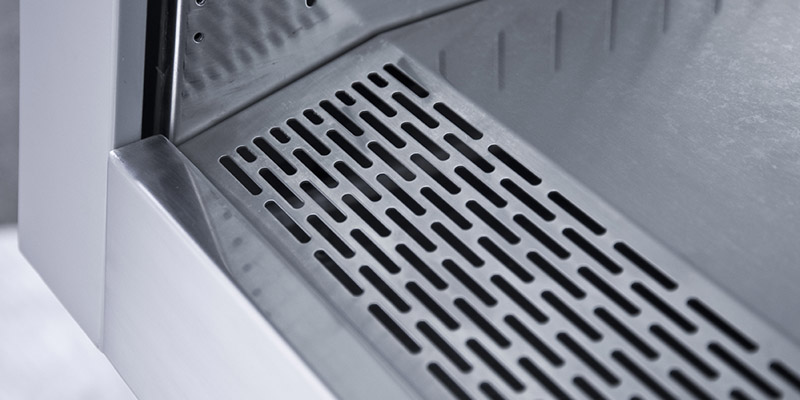

The safety of a Biosafety Cabinet (BSC) depends on its ability to be decontaminated, so the cleanability factor is an essential consideration when making a selection. It should be cleaned both before and after use, as well as after any sizeable spillages.

A single-piece work tray is designed with a recessed area that can contain any accidental spillage. Its integrated design prevents liquid from dripping down, but it is more difficult to clean because it is bulkier than a multi-piece tray.

The multi-piece work tray is a great option for those who are looking for something lightweight and easy to manage. It’s a great choice for cleaning since it’s easy to carry around, but it’s important to note that spills may not be contained as well due to the divided sections.

7. Front Sash Opening Way and Material

When selecting a biological safety cabinet, the user must consider which window mechanism is most suitable for their needs without sacrificing safety.

Hinged windows. They are desirable for their convenient, pre-set opening height. However, for added protection, an additional front cover must be attached when UV light is being employed.

Manual sash window. When operated, it is essential to adhere to the recommended window opening height, which is indicated by the guide mark and is reinforced by the sash alarm. Prior to activating the UV light, the sash window must be entirely shut.

Motorized sash window. It can be operated with the simple press of a button or two. But in order to ensure that the operator’s hands are clear of the window’s path, two buttons are usually employed as a safety measure.

Tempered or laminated safety glass is the preferred material for the sash of biosafety cabinets. This type of glass is usually UV absorbing, clear and can stay in one piece if broken, preventing any containment issues or accidents.

The sash may be either vertical or sloped. A vertical window is easier to construct but may cause eye strain to the user. To address this, many recent models of biosafety cabinets have an angled or sloping front to ensure good visibility while reducing glares and reflections.

8. Energy Efficiency

Power efficiency is a key priority when it comes to selecting a biological safety cabinet. Not only does this minimize energy costs and reduce your carbon footprint, but it also ensures that your equipment is running at top efficiency. To achieve this, the biosafety cabinet should have an impressively low power consumption rate. This means that your cabinet will be able to operate at maximum capacity without using excessive energy, allowing you to get the most out of your equipment without having to worry about your electric bill.

Furthermore, it helps to protect the environment by reducing the overall emissions that come from powering your equipment. When you invest in a biosafety cabinet, it’s important to make sure that it is designed with energy efficiency in mind so that you can be sure you’re getting the best performance for your money.

9. Cost Considerations

When selecting a biological safety cabinet for your lab, it’s important to consider the initial cost. While it’s important to invest in quality equipment to ensure the safety of your lab personnel and the integrity of your research, you also want to make sure that the cost is within your budget. Finding the right balance between quality and affordability is key to ensure your lab is equipped with the best possible biosafety cabinet.

When it comes to making a major purchase, it’s important to look beyond the sticker price and consider the long-term costs. After you’ve taken the plunge and brought your new item to your lab, you’ll need to factor in energy consumption, regular maintenance, and potential repairs down the line. Doing so will help you get the most out of your investment and ensure you’re not hit with any unexpected bills.

Conclusion

In conclusion, selecting a biological safety cabinet is an important investment for any laboratory that deals with hazardous materials. The selection process can be overwhelming, but considering these nine key factors can help ensure that the chosen cabinet meets the laboratory’s needs and requirements. The cabinet’s size, type, and airflow direction are crucial aspects to consider to ensure effective containment of hazardous materials. The quality and integrity of the filters should be examined to ensure that the cabinet provides a safe working environment. The availability of accessories, such as UV lamps and gas ports, can improve the cabinet’s functionality.

In addition, user-friendliness, ergonomics, and serviceability are also important factors to consider when choosing a biological safety cabinet. By keeping these factors in mind, laboratory personnel can make an informed decision when selecting a biological safety cabinet that meets their laboratory’s specific needs and requirements.

Unicorn Lifescience and its Biological Safety Cabinets

As a professional manufacturer of lab equipment, we know the importance of biosafety in laboratory settings. That’s why we’re excited to introduce you to our advanced Biological Safety Cabinet, designed to provide the highest level of protection for lab workers, precious samples and environment.

Please submit the following form and get the latest brochure from Unicorn.