Type

| Type of BSC | Class Ⅱ Type B2 | Class Ⅱ Type B2 | Class Ⅱ Type B2 |

| Dimensions | Nominal Size | 3 feet | 4 feet | 5 feet |

| Usable Working Area | 0.672㎡

7.23 sq.ft. | 0.8736 ㎡

9.40 sq.ft. | 1.0752 ㎡

11.57 sq.ft. |

| Stand Height (mm) | 640mm(Adjustable) | 640mm(Adjustable) | 640mm(Adjustable) |

Internal Work Area,

Dimensions(WxDxH) | 1000*672*630mm | 1300*672*630mm | 1600*672*630mm |

External Dimensions

with Base Stand(WxDxH) | 1180*790*2080mm | 1480*790*2080mm | 1780*790*2080mm |

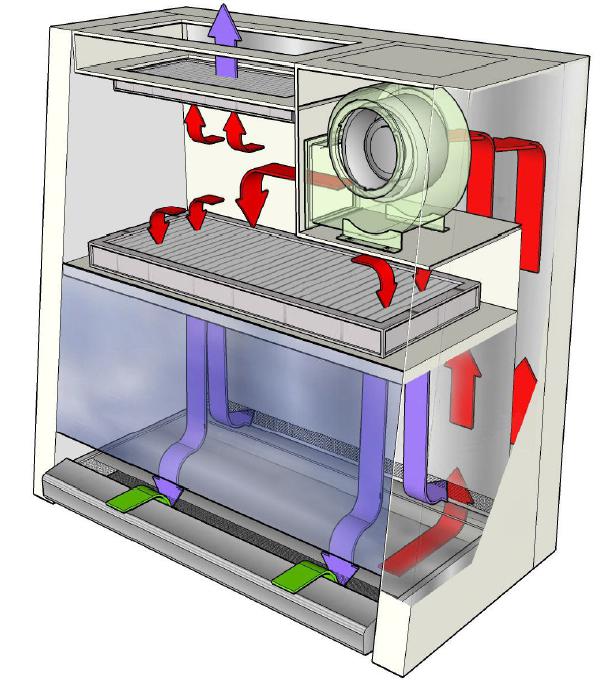

| Airflow | Airflow Mode | 100% exhaust | 100% exhaust | 100% exhaust |

| Exhaust Direction | Top Exhaust | Top Exhaust | Top Exhaust |

| Average Inflow Velocity | 0.53m/s | 0.53m/s | 0.53m/s |

| Average Downflow Velocity | 0.35m/s | 0.35m/s | 0.35m/s |

| Inflow Airflow Volume | 1141m3/h | 1484m3/h | 1826m3/h |

| Downflow Airflow Volume | 798m3/h | 1038m3/h | 1277m3/h |

| Exhaust Airflow Volume | 1141m3/h | 1484m3/h | 1826m3/h |

| Velocity Meter Accuracy | 0.001m/s | 0.001m/s | 0.001m/s |

| Construction | Blower | AC | AC | AC |

| Downflow filter | ULPA | ULPA | ULPA |

| Exhaust filter | ULPA | ULPA | ULPA |

| Main Body | 1.2mm (xxx'') 18 gauge Electro-galvanized steel with white oven-baked powder-coated finish |

| Work Zone | 1.5mm (xxx'') 16 gauge Stainless steel, type304, Single-piece or 3-piece |

| Side Walls | 1.5mm (xxx'') 16 gauge Stainless steel, type304 |

| Sash Glass Thickness | 5mm | 5mm | 5mm |

| Sash Glass Type | Tempered Glass, UV-proof | Tempered Glass, UV-proof | Tempered Glass, UV-proof |

| Sash Window Working Opening | 180mm | 180mm | 180mm |

| Sash Tested Opening | 180mm | 180mm | 180mm |

| Sash Maximum Opening | 530mm | 530mm | 530mm |

| Fluorescent Light Intensity | ≥700lux | ≥700lux | ≥700lux |

| RMS | ≤3um | ≤3um | ≤3um |

| Sound Emission (dBA) | ≦65dBA | ≦65dBA | ≦65dBA |

| Cleanliness | Cleanliness | ULPA: Class 3(ISO 14644.1); Class 100 (Fed 209E) |

| Filter Typical Efficiency | >99.999% at 0.1 to 0.3 micron, ULPA as per IEST-RP-CC001.3 USA |

| Total colony in impaction sampler (Operator Protection) | ≤10CFU./Time | ≤10CFU./Time | ≤10CFU./Time |

| Total colony in slit type sampler (Operator Protection) | ≤5CFU./Time | ≤5CFU./Time | ≤5CFU./Time |

| Total colony in culture dish (Prooduct Protection) | ≤5CFU./Time | ≤5CFU./Time | ≤5CFU./Time |

| Total colony in culture dish (Cross contamination) | ≤2CFU./Time | ≤2CFU./Time | ≤2CFU./Time |

| Personnel Protection Test | KI-Discus containment and microbiological testing are performed |

| Controller | Display | 7 inches touch screen | 7 inches touch screen | 7 inches touch screen |

| UV Timer | Yes | Yes | Yes |

| Main Power Switch | Yes | Yes | Yes |

| Electrical Data | Cabinet Full Load Amps (FLA) | 2.2A | 2.2A | 2.2A |

| Optional Outlet (FLA) | 6A | 6A | 6A |

| Norminal Power Consumtion (W) | 1500W(Excluding external exhaust fan) | 1500W(Excluding external exhaust fan) | 1500W(Excluding external exhaust fan) |

| Power Supply | AC220±10%,50/60HZ | AC220±10%,50/60HZ | AC220±10%,50/60HZ |

| Alarm | Alarm Type | Audible + Visual | Audible + Visual | Audible + Visual |

| Inflow Velocity | Yes | Yes | Yes |

| Downflow Velocity | Yes | Yes | Yes |

| Sash Height limit | Yes | Yes | Yes |

| Filter Blocked | Yes | Yes | Yes |

| Filter Lifetime Remind | Yes | Yes | Yes |

| Accessories | Fluorescent lamp | 30W*2 | 30W*2 | 30W*2 |

| Ultraviolet lamp | 30W*1 | 30W*1 | 30W*1 |

| Receptacle (Pieces/Power/Current) | 1 | 1 | 1 |

| Detachable Base Stand | Yes | Yes | Yes |

| Wheels | Yes | Yes | Yes |

| Gas Valve | Optional | Optional | Optional |

| Vcuum Valve | Optional | Optional | Optional |

| Water Valve | Optional | Optional | Optional |

| Arm Rest | Optional | Optional | Optional |

| I.V. Pole | Optional | Optional | Optional |

| Canopy connection | Optional | Optional | Optional |

| Weight | Net Weight (kg) | 280 Kg (617 lbs) | 300Kg (661 lbs) | 330 Kg (727 lbs) |

| Gross Weight (kg) | 305Kg (606 lbs) | 330Kg (661 lbs) | 370 Kg (750 lbs) |

| Shipping | Packing size (WxDxH) | 1310*950*2220mm | 1610*950*2220mm | 1910*950*2220mm |

| Shipping Volume | 3.06m³(108.06 ft3)(Including external exhaust fan) | 3.70 m³(130.66 ft3)(Including external exhaust fan) | 4.33 m³(152.91 ft3)(Including external exhaust fan) |

| Standard | Certificates | CE, EN12469, ISO9001, ISO13485, CFDA YY0569 |