Why Airflow Makes Your Biosafety Cabinet Safe

A biosafety cabinet (BSC) is your main shield of protection in the lab. It uses carefully controlled air movement to keep you safe from dangerous materials, protect your experiments, and stop harmful microorganisms from escaping into the environment. The most important part of this protection system is the biosafety cabinet airflow.

Now, it’s really important to understand something fundamental about most of the BSCs you’ll encounter, particularly Class II cabinets: they are considered ‘partial barrier systems.’ This might sound a bit technical, but it’s a key idea. Unlike some ultra-high containment devices like Class III cabinets (which are completely sealed boxes that you work in using built-in gloves), a Class II BSC doesn’t rely on a solid, physical wall all around to keep you safe. Instead, its primary protection comes from that carefully controlled, dynamic movement of air we just mentioned – the invisible shield.

This means the cabinet’s ability to protect you is directly tied to how well that airflow is maintained. If the airflow patterns are disrupted, the shield can weaken or even break. This is why understanding how the air moves and what you can do to keep it flowing correctly is so incredibly important.

Think of this airflow as an invisible shield that works in different directions. The cabinet pulls air in from the front opening where you work. At the same time, it pushes clean air downward inside the work area and sends contaminated air out through special filters. These air movements create barriers that harmful particles cannot cross.

Different biological safety cabinet classes use different airflow patterns to match various safety needs. Each pattern is designed to handle specific kinds of risks.

How Biosafety Cabinets Work: Understanding Air Movement

To work safely with your BSC, you need to know that it’s doing its job correctly. The cabinet must maintain steady air movement at all times. When the airflow works as designed, you can focus on your research knowing you’re protected. This guide will show you how these airflow patterns work and what you can do to keep your BSC working effectively.

A biosafety cabinet (BSC) keeps you and your work safe through careful control of air movement. The way air flows inside these cabinets follows simple but important rules that every lab worker should know. Understanding these basics will help you work more safely and get better results.

Clean Air Flow: The Foundation of Safety

A cornerstone of how a BSC protects your experiments is through something called laminar flow, which you might also hear referred to as unidirectional flow. Imagine air moving in perfectly straight, parallel streams, like lanes on a highway, with no mixing or swirling between them. That’s laminar flow. In most Class II BSCs, this is a steady, gentle shower of HEPA-filtered air flowing straight down from the top of the cabinet over your entire work area.

If the air inside the cabinet were turbulent, swirling around like a chaotic wind, it would be impossible to keep contaminants out or to effectively remove any generated aerosols. So, this highly controlled, smooth laminar flow is fundamental to the BSC’s ability to provide a sterile and safe working space

Air Flow Through HEPA/ULPA filters

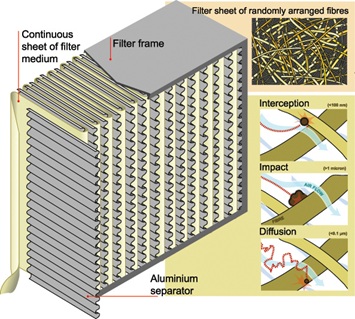

HEPA filters are the workhorses that keep the air clean. But how do they really do it? It’s not like a simple kitchen sieve. Inside a HEPA filter, there’s a dense mat of super-thin glass microfibers, all tangled together and folded like an accordion to create a huge surface area. This clever design allows them to trap tiny particles, like bacteria and viruses, in a few key ways

Impaction: Imagine larger, heavier particles trying to navigate a maze. They have too much momentum to follow the air’s curving path around the filter fibers. Instead, they barrel straight ahead and impact a fiber, getting stuck. This is very effective for particles larger than about 1 micrometer.

Interception: Mid-sized particles are lighter and can follow the airflow. However, if their path takes them very close to a fiber – so close that the particle’s edge touches the fiber – they get snagged or intercepted. Think of it like a ball rolling just a bit too close to a curb and getting caught. This typically happens with particles in the range of 0.3 to 1 micrometer.

Diffusion (Brownian Motion): Now for the tiniest particles, like individual virus particles (often smaller than 0.1 micrometers). These are so light they get constantly bumped around by air molecules, causing them to move in a random, zig-zag pattern called Brownian motion. This chaotic dance greatly increases their chances of diffusing towards and colliding with a fiber, where they stick.

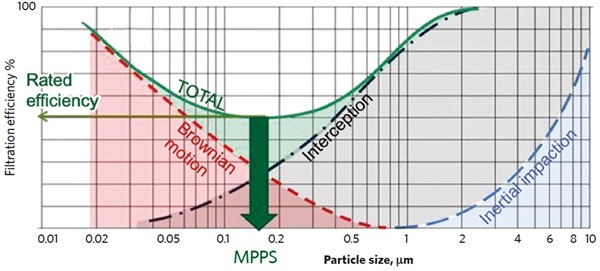

Here’s a fascinating detail: HEPA filters are famously rated for their efficiency at capturing particles of a specific size – usually 0.3 micrometers (µm). This size isn’t the smallest particle they can catch. In fact, it’s known as the Most Penetrating Particle Size (MPPS). This means it’s the particle size that’s theoretically the trickiest for the filter to capture. Standard HEPA filters are incredibly good, trapping at least 99.97% of these 0.3 µm particles. Paradoxically, they are often even more effective at capturing particles that are both larger and significantly smaller than this MPPS! Larger particles are easily caught by impaction and interception, while much smaller ones are very effectively nabbed by diffusion.

For situations requiring even higher levels of air purity, there are ULPA (Ultra-Low Penetration Air) filters. These can capture 99.999% or more of particles at their MPPS (which is usually around 0.12 µm). However, HEPA filters remain the standard for most biosafety cabinets. This is because they provide excellent protection against the microbes we’re typically concerned about (which are often larger themselves or attached to bigger droplets or particles), and ULPA filters generally create more resistance to airflow, which can affect cabinet design and energy use.

Three Key Air Movements

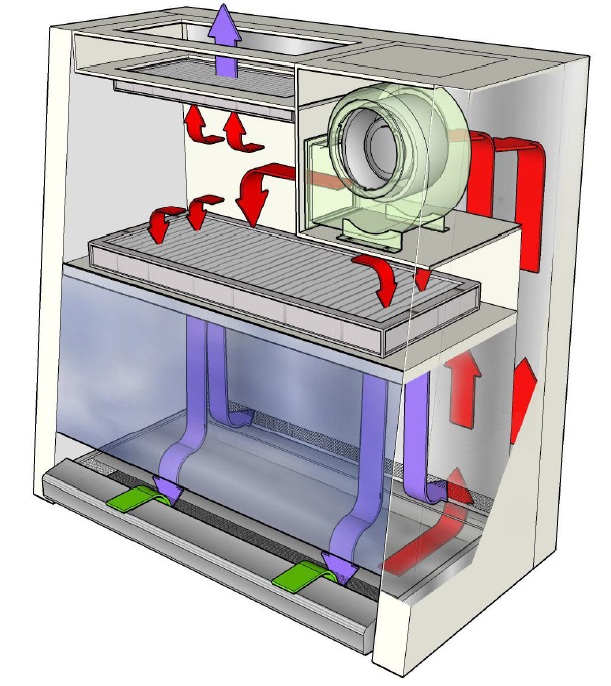

The BSC uses three main air flows to protect you and your work. Underlying all these movements is a crucial concept called negative pressure. Essentially, the cabinet is engineered so that the air pressure inside its work area and internal ductwork is slightly lower than the air pressure in the surrounding laboratory. This is a key safety feature. If there were any tiny leaks, room air would be drawn in, preventing hazardous materials from escaping out. This negative pressure environment is a cornerstone of how the cabinet contains potential hazards.

Now, let’s look at the specific air movements:

Inflow: Room air gets pulled into the cabinet through the front opening. This creates an invisible air curtain that acts like a protective barrier, keeping any dangerous materials generated inside from escaping out to you. This inflow air, also known as face velocity, needs to move at a specific minimum speed to be effective. This speed isn’t a one-size-fits-all, but rather depends on the type of Class II cabinet:

Picture these key parts working together:

This basic design works well for most lab work. However, some labs need special types of cabinets for work with chemicals or radioactive materials. These cabinets might send all their air outside instead of recycling it.

- An intake grille at the front where room air enters

- A work surface where you handle materials

- HEPA filters that clean the air

- A fan that keeps air moving

- Inner channels that guide air flow

- An exhaust system that releases clean air

Remember: Each part of this air system has a purpose. When they all work together, they create a safe space for handling dangerous materials in the lab.

Downflow: Clean, filtered air flows straight down from the top of the work area. This steady stream of clean air keeps contaminants away from your samples. Think of it as a constant shower of pure air washing over your work.

Exhaust: Used air must leave the cabinet safely. Before it goes anywhere, this air passes through HEPA filters to remove any dangerous materials. Some cabinets send this clean air back into the lab, while others pipe it outside the building.

When these three air movements work together perfectly, they create a safe space for handling dangerous materials. The design is simple but effective, protecting you, your samples, and the lab environment all at once.

How Air Moves in Class II Biosafety Cabinets

Biosafety cabinets protect lab workers and their samples from harmful substances. These special workstations create carefully controlled air patterns that keep everyone safe. Understanding how air moves in your biosafety cabinet is key to using it properly and staying protected.

Three Ways Biosafety Cabinets Keep You Safe

Protecting People: Air flows inward through the front opening like an invisible shield. This air movement stops dangerous particles from reaching the person working at the cabinet.

Protecting Samples: Clean, filtered air flows down over your work area in a steady stream. The downward flow keeps dust and other contaminants away from sensitive materials.

Protecting the Environment: Special HEPA filters clean all the air that leaves the cabinet. This filtration ensures no harmful substances escape into the lab or outside world.

Following the Air’s Path

Room air first enters through intake grille in the front of the cabinet. This incoming air then mixes with some of the clean, filtered air near the work surface. A fan pulls this mixture up through the cabinet’s inner walls. At the top, what happens next depends critically on the specific **type of Class II biosafety cabinet you’re using. While a common pattern involves recirculating a large portion of air, not all Class II cabinets work this way. Understanding these differences is key, especially if your work involves chemical fumes.

All these details about different airflow patterns and exhaust methods can seem like a lot to take in. To make it clearer, here’s a table that summarizes the key differences between the common Class II biosafety cabinet subtypes

Key Differences Among Class II Biosafety Cabinet Subtypes

| Feature | Class II Type A1 | Class II Type A2 | Class II Type B1 | Class II Type B2 (Total Exhaust) | Class II Type C1 |

|---|---|---|---|---|---|

| Air Recirculation | ~70% | ~70% | ~30% (Front of work area) | 0% | Variable: ~70% (A-mode) or 0% in exhausted zones (B-mode) |

| Air Exhaust | ~30% | ~30% | ~70% (Rear of work area) | 100% | Variable: ~30% (A-mode) or 100% from exhausted zones (B-mode) |

| Exhaust Method | To room (or optional thimble) | To room or thimble/canopy connection | Hard-ducted to building exhaust | Hard-ducted to building exhaust | To room (A-mode) or hard-ducted (B-mode) |

| Chemical Vapor Use | Not recommended (if exhausted to room) | Minute amounts (non-toxic, if canopied) | Low levels (in directly exhausted rear zone) | Yes (preferred for significant quantities) | Yes (when in B-mode and ducted, for specific zones) |

| Key Feature/Note | Older design; potentially positive pressure contaminated plenums | Most common type; contaminated ducts under negative pressure or surrounded by negative pressure | For low-level chemical work in designated area; specific airflow zones | No recirculation; best for volatile chemicals; requires exhaust interlock | Flexible; can switch between recirculating and ducted (for chemical) operation |

As you can see from the table, the biggest differences lie in how much air is recirculated versus exhausted, how the air is exhausted (back into the room or out of the building), and critically, how well each type handles chemical fumes. This is why choosing the right type of BSC for your specific work is absolutely essential for safety.

How to Keep Your Biosafety Cabinet Working Safely

A biosafety cabinet protects you by creating an invisible shield of moving air. This carefully controlled airflow keeps dangerous materials inside the cabinet and prevents outside air from getting in. Understanding how to maintain this protective shield is crucial for everyone’s safety.

Common Problems That Can Break the Air Shield

hat invisible shield of air in your biosafety cabinet is powerful, but it’s not invincible. Several issues, some from how we work and some from the cabinet itself, can weaken or even break this protective barrier. Understanding these common problems – and why they happen and what the consequences are – is key to staying safe.

Here’s a draft of a checklist-style table:

BSC Airflow Safety: Common Disruptors & How to Stay Protected

| Disruptor / Potential Problem | Why It’s a Problem / Potential Risk | How to Avoid / Checkpoint |

|---|---|---|

| 1. Blocked Air Grilles (Front or Rear) | Weakens protective inflow (front); disrupts downflow, causes dead spots, cross-contamination (rear). Risk to personnel & product. | Keep grilles completely clear of papers, equipment, arms. Allow air to flow freely. |

| 2. Overcrowding the Cabinet | Obstructs downflow, creates turbulence. Risk of product contamination (external & cross-contamination). | Bring only necessary items into the BSC. Arrange items to allow air to flow around them. |

| 3. Rapid Arm Movements / Poor Technique | Can “drag” contaminants out or push room air in, temporarily breaking the air curtain. Risk to personnel & product. | Move arms slowly and deliberately in and out. Minimize movements. Work “clean to dirty.” Wait a minute after entry. |

| 4. External Air Drafts | Can overwhelm the cabinet’s air barrier (inflow). Risk to personnel & product. | Locate BSC away from doors, high traffic, AC vents. Minimize activity around the BSC. |

| 5. Incorrect Sash Height / Damaged Sash Gaskets | Compromises inflow air barrier strength. Risk to personnel. | Always operate with the sash at the certified height. Regularly check sash gaskets for wear/damage. |

| 6. Clogged HEPA Filter(s) | Increases airflow resistance; reduces inflow & downflow speeds. Weakens all protection. Risk to personnel, product, & environment. | Ensure regular BSC certification (includes filter checks). Monitor pressure gauges if equipped. |

| 7. Motor / Blower Malfunction | Insufficient or erratic airflow. Cabinet cannot maintain protective speeds. Risk to personnel, product, & environment. | Listen for unusual noises. Report any suspected issues immediately. Ensure regular BSC certification. |

| 8. Building Exhaust Failure (for Ducted BSCs, esp. Type B2) | CRITICAL RISK! Can cause positive pressure in Type B2, forcing contaminants out of BSC. High risk to personnel & environment. | Ensure Type B2 BSC has a working interlock with building exhaust. Know emergency procedures for exhaust failure. |

| 9. Open Flames Inside BSC | Creates severe turbulence, damages HEPA filters, fire hazard. Disrupts all protection. | DO NOT USE OPEN FLAMES. Use disposable loops or electric incinerators. |

| 10. Improper Equipment Placement | Large items can block airflow patterns, creating “dead zones” or turbulence. Risk to product. | Place large equipment to the sides or elevate it to allow air to flow underneath. Avoid placing directly under downflow. |

Working Safely in Your Cabinet

Always turn on the cabinet 5-10 minutes before you start working. This cleans out any dust or contaminated air inside. Clean all surfaces with disinfectant before and after each use.

Keep your work at least 4-6 inches back from the front opening. This simple step keeps you in the safest part of the cabinet. Move your arms slowly and straight in and out of the cabinet, like you’re reaching through an invisible curtain.

Don’t overcrowd your workspace. Having too many items in the cabinet blocks airflow and creates dangerous spots where contaminated air can collect. Bring in only what you need for your current task.

When you finish working, let the cabinet run empty for 3-5 minutes. This final step ensures all contaminated air is cleared out. Wipe down everything with disinfectant before removing it from the cabinet.

Advanced Safety Features: Monitoring Air in Biosafety Cabinets

How Monitoring Systems Work

Good airflow in biosafety cabinets keeps lab workers safe. Modern cabinets use special gauges and digital screens to constantly check the air movement inside. These monitoring devices show if the air is moving at the right speed to protect people and samples. Some new cabinets have smart systems that automatically keep the airflow just right.

The cabinet’s alarm system protects workers when something goes wrong. It uses both sound and flashing lights to warn users about unsafe conditions. The specific meaning of different alarm signals can vary by cabinet model, so always refer to your cabinet’s manual.

Safety Rules and Regular Checks

The U.S. has strict rules about how biosafety cabinets should work. These rules are called NSF/ANSI 49, and they cover everything about the cabinets. Expert technicians must check each cabinet regularly to make sure it’s working properly. They test the air speed, check the special filters, and make sure the alarms work correctly.

Where you put the cabinet matters a lot for safety. The cabinet needs to be away from busy areas in the lab. Doors and air vents can disturb the airflow, so keep the cabinet away from them. A well-placed cabinet in a quiet spot works best to keep everyone safe.

To ensure biosafety cabinets consistently do their job of protecting you, your work, and the environment, there are strict industry standards that govern their design, performance, and testing.

In the United States, the primary standard is NSF/ANSI 49. This comprehensive document, developed by NSF International and the American National Standards Institute, lays out detailed requirements for Class II (laminar flow) biosafety cabinets. It’s not just a simple rulebook; it specifies critical aspects like:

Minimum Inflow Velocities: As we discussed, this includes precise speeds like 75 fpm for Type A1 cabinets and 100 fpm for Type A2, B1, and B2 cabinets, ensuring that protective air barrier is strong.

HEPA Filter Efficiency: It mandates the use of HEPA filters that meet stringent particle capture efficiencies (for example, removing at least 99.99% of 0.3 micrometer particles, according to some interpretations of the standard, though the general HEPA definition is often 99.97%).

Design and Construction: This covers everything from the materials used (to ensure they are durable and easy to clean) to limits on noise and vibration, and even proper lighting levels inside the cabinet.

Performance Testing: NSF/ANSI 49 outlines a whole suite of tests that cabinets must pass to prove they provide effective personnel, product, and environmental protection. This includes tests for airflow patterns, filter integrity, and cabinet leak tightness.

In Europe, a similar key standard is EN 12469. While both NSF/ANSI 49 and EN 12469 aim to ensure BSC safety, they have some differences in their specific requirements, such as exact airflow velocities, HEPA filter classification (e.g., EN 12469 might specify an H14 filter, which has an efficiency of ≥99.995% at the Most Penetrating Particle Size), and particular testing protocols.

Why do these standards matter so much? They provide a benchmark for manufacturers to build safe and reliable cabinets. More importantly for you, they form the basis for field certification. Expert, certified technicians use these standards when they inspect and test your cabinet – typically upon installation, at least once a year, and any time it’s moved or has significant maintenance (like a filter change). This regular certification, which includes checking airflow speeds, HEPA filter integrity, and alarm functions, is your assurance that the cabinet is performing as designed and continuing to keep you safe.

Conclusion: Creating a Safer Lab with Your BSC Airflow

A biosafety cabinet’s airflow system is key to keeping your lab safe and your work reliable. The system uses special HEPA filters and carefully controlled air movements to protect you, your samples, and the environment around you in multiple ways. Understanding how air moves through your BSC is not complicated, but it matters a lot. You need to follow the right steps when using the cabinet and watch out for anything that might block or change the airflow. Make sure experts check and certify your BSC regularly – it’s part of keeping everyone safe in the lab. When you respect these basic rules and keep learning about your equipment, you help create a better and safer place for research.